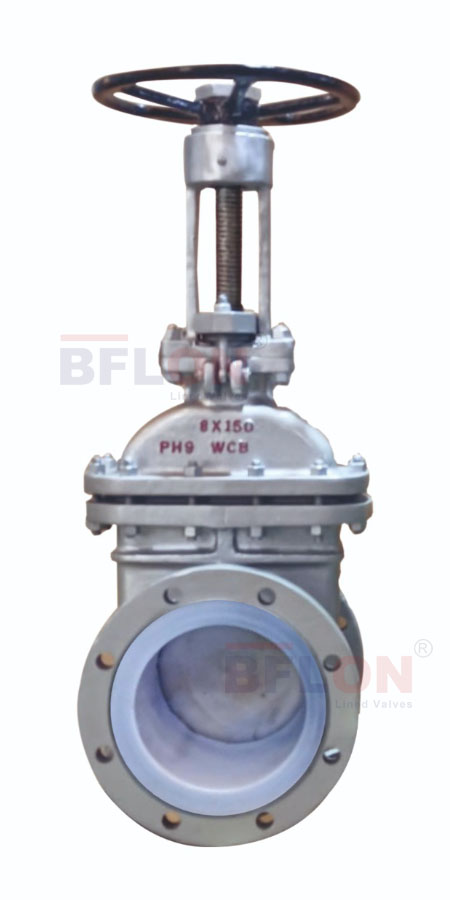

Lined Gate Valve

STANDARD SPECIFICATIONS

| Design Standard | API 600 / ASME B 16.34 |

| Testing Standard | API 598 / BS EN 12266-1 |

| End Connection | Flanged End |

| Face to Face | ASME B 16.10 |

| Flange Drilling | ASME B 16.5 150# / JIS / DIN 2501/2632/2633 / BS 4504 / Others on order |

| Pressure Rating | 150# / PN10 / PN16 |

| Leakage Class | Class VI (Zero Leakage) as per API 598 |

| Size Range | From DN25 (1”) TO DN 300 (12”) Size |

| Operation | Manual Hand Wheel Operated |

| Bevel Gear Operated | |

| Pneumatic Single Acting (Spring Return) Cylinder Actuator Operated | |

| Pneumatic Double Acting Cylinder Actuator Operated | |

| Electrical Actuator Operated (Motorized Operated) | |

| Flow Direction | Bi-Directional |

MATERIAL OF CONSTRUCTION

| Body, Bonnet & Wedge | ASTM A 216 GR. WCB (Cast Carbon Steel) |

| ASTM A 351 GR. CF8 (SS 304) | |

| ASTM A 351 GR. CF3 (SS 304L) | |

| ASTM A 351 GR. CF8M (SS 316) | |

| ASTM A 351 GR. CF3M (SS 316L) | |

| Lining | FEP (ASTM D 2116) - Fluorinated Ethylene Propylene |

| PFA (ASTM D 3307) – Perfluoroalkoxy Alkane | |

| ETFE (ASTM D 3159) - Ethylene Tetrafluoroethylene | |

| PTFE (ASTM D 4895 - Polytetrafluoroethylene | |

| PVDF (ASTM D 3322) - Polyvinyldiene Fluoride | |

| PP (ASTM D 4101) - Polypropylene | |

| HDPE - High Density Poly Ethylene | |

| Lining Thickness | 3 To 5mm |

JUST GIVE US YOUR PROCESS DATA AND BE FREE

WE WILL SUGGEST TYPES OF BFLON PTFE LINED VALVES

- Name of Flow Media (Passing Through Line)

- Working Pressure

- Working Tempertaure (CORRECT SPELLING HERE AS Temperature)

- Valve Size or Line Size

- Required Quantity

- Type of Valve

PRESSURE TESTING

| Body (Hydrostatic) | 15.0 Kg./Cm2 |

| Seat (Hydrostatic) | 10.0 Kg./Cm2 |

| Testing Media | Water at Room Temperature |

| Lining Test/Spark Test | 15 KV DC |

LET'S GIVE YOUR PLANT "MAINTENANCE FREE" LOOK

Bflon PTFE Lined Valves - "WHERE SOLUTION FLOW"

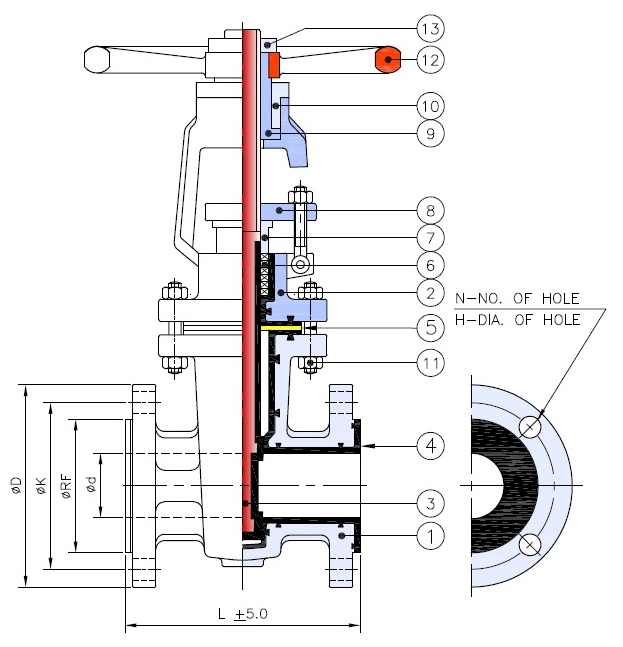

Dimensions [150 Class]

| Size(mm) | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 |

| Size(inch) | 1" | 1½" | 2" | 2½" | 3" | 4" | 6" | 8" | 10" | 12" |

| L | 127 | 165 | 178 | 192 | 203 | 229 | 267 | 292 | 330 | 356 |

| Ød | 25 | 38 | 50 | 65 | 75 | 100 | 150 | 200 | 250 | 300 |

| O.D. ØD | 110 | 125 | 150 | 180 | 190 | 230 | 280 | 345 | 405 | 485 |

| P.C.D. ØK | 79.2 | 98.5 | 120.6 | 139.7 | 152.4 | 190.5 | 241.3 | 298.4 | 362 | 431.8 |

| R.F.DIA. ØRF | 50.8 | 73.0 | 92.1 | 104.7 | 127.0 | 157.2 | 215.9 | 269.9 | 323.8 | 381 |

| No. OF HOLE N | 4 | 4 | 4 | 4 | 4 | 8 | 8 | 8 | 12 | 12 |

| HOLE DIA. ØH | 15.8 | 15.8 | 19 | 19 | 19 | 19 | 22 | 22 | 25.4 | 25.4 |

Nomenclature

| SR. NO. | DESCRIPTION | MOC |

|---|---|---|

| 1 | BODY | WCB/CF8/CF8M/CF3/CF3M |

| 2 | BONNET | WCB/CF8/CF8M/CF3/CF3M |

| 3 | WEDGE WITH STEM | WCB/CF8/CF8M/CF3/CF3M |

| 4 | BODY+BONNET LINING | FEP / PFA |

| 5 | GASKET | PTFE |

| 6 | GLAND PACKING | PTFE |

| 7 | GLAND BUSH | S.S. 304/316 |

| 8 | GLAND FLANGE | C.S./S.S. 304/316 |

| 9 | SPINDLE NUT | S.G. IRON |

| 10 | BONNET NUT | C.S. |

| 11 | HAND WHEEL | S.G. IRON |

| 12 | HAND WHEEL NUT | C.S. |

| 13 | FASTENERS | B7-2H/S.S. 304 |

FEATURES

- Rising Stem

- OS & Y Type

- Bolted Bonnet

- Deep Stuffing Box for Gland Packing

- Two Piece Self Aligning Gland Flang

Application of PTFE / FEP / PFA / Fluoropolymer / Plastic Lined Valves, Lined Pipe Fittings, Lined Y Strainer, Lined Basket Filters, Lined Sight Glass & Sight Flow Indicators.

- Pulp & Paper Mill

- Chemical & Agro-Chemical Plant

- Alkali's & Chlorine Plant

- Sugar Mill

- Pharmaceuticals Industries

- Metal and Mining Industries

- Bromine Plant

- Water Treatment Plant

- Organic Chemical Plant

- Hydrocarbon Plant

- Detergent & Soap Industries

- Power Generation Plant

- Fertilizer Industries

- Oil & Gas Plant

- Sulfur Recovery Plant

- Aggressive Vapors

- Phosphorus & Acid Services

- Corrosive Application